Recently, Conspectus participated in two conferences: Construction Owners Association of America (COAA) and Lean Construction Institute's Lean in Design Forum. Both groups are searching for a means to improve construction project delivery with some common themes. Principal among them is PEOPLE.

The COAA Way begins with a "Good Owner" and assembles teams and organization that make up the project. Lean Construction Institute identifies "Respect for People" as the primary tenet for a successful project.

Why the focus on PEOPLE? The answer is obvious.

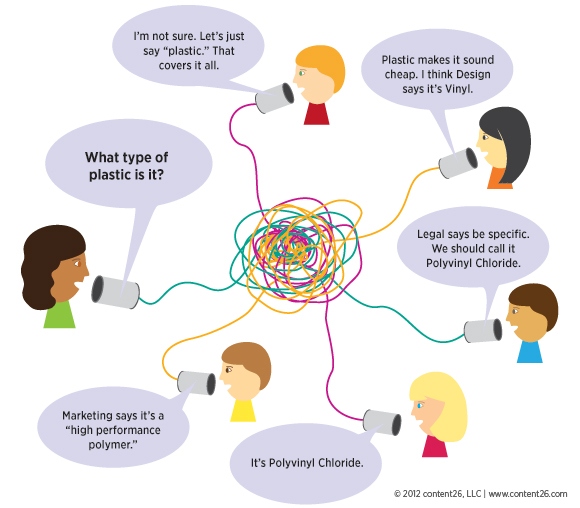

Communications! People interact and talk with each other. The importance of

communications cannot be overstated. The market must be able to communicate

needs and then the market must be able to respond to fulfill those needs. When communications

fail to occur or when communications are misunderstood, the market cannot

respond efficiently, and the needs may never be completely fulfilled.

How does this apply to construction? The owners require a

building. They communicate the needs via a building program, owner project

requirements, a budget, and a completion time. At this point, the universe is

essentially the solution. Constraints must be set to narrow the focus and the

set of potential solutions. The constraints start with the owner's project

requirements formed from the business case dictating the need for a capital

project. Each constraint must be fully communicated to the design and

construction teams and recorded. Then design ideas can be applied and

alternatives identified to solve the problem. When each step and each input is

recorded in a transparent fashion the entire team, design and construction, can

contribute so an optimal solution can be found. Then the solution can be validated

as compliant against all the recorded constraints. When the information is comprehensive, the

solution may be validated continuously: during design, construction, and

occupancy.

Projects must combine the talents of hundreds of individuals

to conceive the project, develop the business case, validate the feasibility,

create the design, execute the construction, and finally operate the building. Each

individual and each group must contribute to the communications, building a

recorded project knowledge base during the process.

The potential perils are many, simply by the sheer number of individuals involved in the process.

The written communication record is important. The record

must be accessible to the entire team as a common foundation for making project

decisions, and the most common mechanisms for communication lack the continuity

and transparency required. Email does not work well because it is parochial,

shared only with selected team members. Email records can prevent individual

access to critical data that influences decisions. Document management systems

do not work well because they record a specific result at a specific point in

time, not the process, and possibly not the ultimate resolution. Without the

benefit of version control, individual documents can mislead by masquerading as

the final resolution.

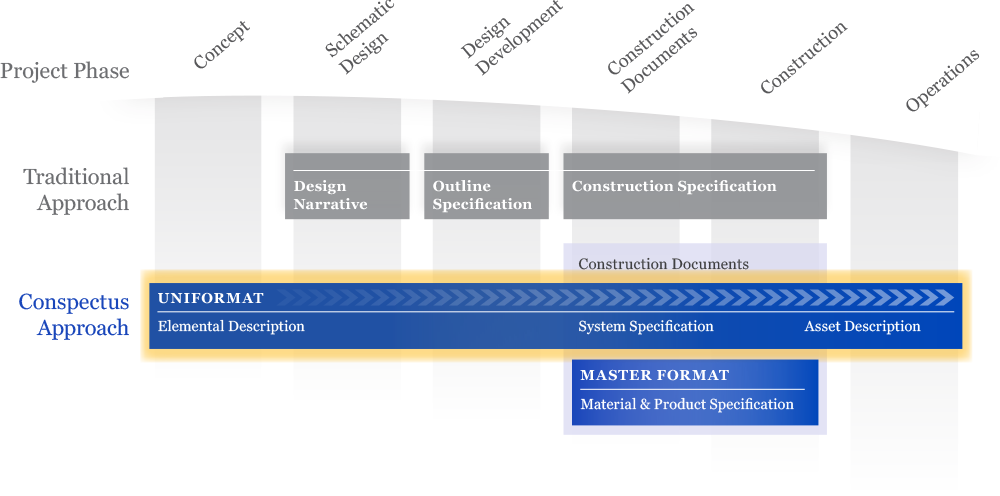

Communications must maintain a continuity from initial exploration to final resolution. The communication must show the ideas, questions, discussions, and decisions leading to the conclusions so the processes and the results are all understood. Make the information stream continuous. Build the project record with each idea and each decision so the entire team is aware and fully informed. Use Uniformat as an additive methodology to "say what you know, when you know it."

Without effective, timely, and seamless communications, the

multiple handoffs during the design and construction process create information

gaps. Every time an individual or team passes the project to the next, there is

the potential pitfall of information loss during the transaction.

The Conspectus approach implements effective communications that are essential to both The COAA Way and Lean Construction.