Certainly, you have seen examples of natural expansion joints. Science rules. Materials move. Buildings react; sometimes not as expected.

For brick masonry three separate forces are at work: moisture movement, thermal movement, and deformation.

When brick is manufactured, it is fired in a 2,000 degree F kiln to harden the clay. Exposure to that elevated temperature evaporates most, if not all, moisture from the clay. When removed from the kiln, the brick immediately begins seeking equilibrium with the ambient conditions by cooling and absorbing moisture.

Brick moisture absorption causes permanent expansion. The majority of the total moisture expansion occurs in the first year. The expansion continues, but at a much reduced annual rate.

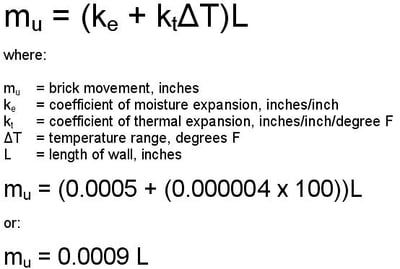

The total moisture expansion can be estimated by using 0.0005 inches/inch as the coefficient of expansion.

Thermal movement is cyclical depending on ambient temperature. The full temperature range for a building's locale should be considered. A 100 degree F temperature range will suffice for most locations in the US.

Brick thermal movement is the product of 0.000004 inches/inch/degree F as thermal coefficient of expansion and the 100 degree F total temperature range. The result is 0.0004 inches/inch thermal movement.

The total expected brick movement is given by the formula:

That's a small number. So what is the big deal? Back to the science.

That's a small number. So what is the big deal? Back to the science.

Mortar joints are normally 0.375 inches wide. ASTM C920 Class 50 elastomeric sealants will accommodate plus or minus 50% joint movement. So the total allowable joint movement is 0.1875 inches.

In a horizontal direction, movement within a masonry panel will affect two sealant joints, one at each end of the panel. Using the 0.0009 inches/inch total movement and 0.1875 inches maximum allowable movement, joints must be spaced no more than 208 inches (17' 4") apart. For greater spacing, wider expansion joints will be required.

In a vertical direction, sealant joints occur only at the top of the masonry panel. The bottom of the panel will bear solidly on the foundation or shelf angle. The sealant joint must accommodate the brick expansion and the shelf or relief angle deflection in a joint with only 0.1875 inches allowable movement. Keep the shelf angle support spacing small to limit deflection movement to near zero because most of the joint movement capacity will be required for brick expansion.

Be sure to consider one other factor: creep. Creep is the permanent deformation of building materials due to long term imposed loads. Creep in brick masonry is negligible because creep occurs primarily in the mortar joints. Creep should be considered if the building structural frame is concrete or concrete masonry. Concrete masonry creep is 2.5 x 10^-7 inches/inch/psi by code. For 1,900 psi net compressive strength concrete block, this movement is 0.00051 inches/inch. In concrete frame structures, creep is even more significant, nearly double. Be sure your structural engineers provide an estimated creep, so you can accommodate the shortening effect of the structural frame in the brick design.

Size the sealant joints to accommodate the expansion joint spacing. But realize there is a practical maximum spacing. The Brick Industry Association recommends maximum 25 feet for walls without openings and 20 feet for walls with multiple openings. Placing joints takes careful consideration of the building geometry, corners, changes in height, offsets, openings and rigid boundaries to list only some.

Learn more about brick movement and expansion joints by reading Brick Industry Association's Technical Notes. Technical Note 18 discusses brick volume change and Technical Note 18a discusses movement joints.