3 min read

Why are Preliminary Project Descriptions (PPDs) Important?

![]() David Stutzman

12/31/12 12:32 PM

David Stutzman

12/31/12 12:32 PM

Short Answer: PPDs document the architect's intended project quality.

Understanding an architectural design and determining the estimated construction cost requires two pieces of information:

- The type and quantity of products shown on drawings and

- The quality required for those products.

How can quality be defined? PPDs document the expected project quality - the quality of the materials, the installation methods, and the required performance of the completed construction - in the same format used by construction estimators.

Preliminary Project Descriptions

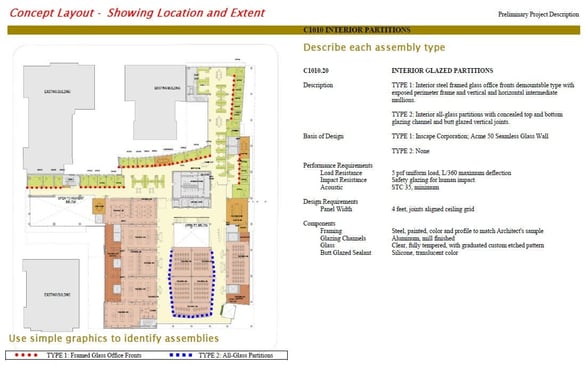

Show location & extent with description

PPDs are a combination of written and graphic information about a construction project used to convey design intent in a form that is understood by owners, estimators, and lenders.

PPDs capture the quality and performance of building functional elements. Unlike specifications, PPDs are arranged by system and assembly. They begin from the bottom-up and then from outside-in (i.e. foundations, superstructure, exterior walls followed by interior partitions, finishes, and fittings). The arrangement follows UniFormat, a system developed by estimators, the same system used by R.S. Means Assemblies Cost Data.

PPDs allow the design team to document performance and design requirements that cannot be shown on drawings. The structural, thermal, aesthetic, and other requirements can be defined to ensure the completed building will meet the code and design expectations. When the design solution for each element is finally decided, the individual component materials of each system can be described.

Like design, PPDs are iterative. As the design progresses, additional detail can be added, easily, to describe the project quality. There is no need to know exactly what brick will be used for the building veneer to be able to describe the exterior wall. Yet, PPDs provide a structure and outline as a checklist to help ensure the known quality requirements are documented.

Options Needed: One fabulous benefit of PPDs is the ability to document design options without drawing them. The options may be for individual materials or complete systems. The preferred building cladding may be terracotta tiles. Because of the potential cost, the architect may be willing consider metal wall panels instead. PPDs describe elements, so the two cladding options become simple statements as part of the exterior wall description.

Architectural Drawings

The first drawings an architect produces will be rough sketches - concepts or images - of what the final design may be. Detail will be lacking, initially. Detail will be added with each iteration as the design is refined, developed, revised, and finally completed ready for construction.

Architectural drawings show relationships, sizes, and aesthetics of the design establishing the overall design image. The drawings also identify the type and quantity of products required to complete the design.

The architect will show the products by their generic name: aluminum window, wood door, brick veneer, metal roofing. As you can imagine, there are many types and qualities of each of product with these generic names.

For Example: Is the wood door a paint grade hollow core door that can be found for $22 at one of the big box stores? Or might the door be a custom design, sketch-face, with inlaid exotic veneers hung in a custom wood frame with specially designed hardware that may cost thousands of dollars?

On the architect's drawings, the door is a wood door, so how will the owner or estimator know what is intended?

Construction Estimates

Estimators count, apply quality requirements to the counts, and then apply installation methods to the counts and quality. Only the counts can be determined from the architect's drawings. So drawings, alone, cannot completely inform a construction estimate.

Without a description of the quality and installation methods, the estimator will make assumptions based on experience. The construction estimate will be misinformed, and the predicted construction cost will be wrong. When the estimator guesses, he will be conservative to ensure the cost is adequately covered.

The Result: Value engineering (cost cutting) exercises to reduce the estimated construction costs based on incomplete information.

Define the Quality

Project scope and material decisions will be made based on undocumented assumptions about quality and methods. Sure, the design can be revised to save $200k in the building cladding. The estimate will be revised. Then the process will be repeated until the quality is defined.

"Insanity: Doing the same thing over and over again and expecting different results" - Albert Einstein.

Stop the insanity! Use PPDs to define the project quality and methods.

Give the estimators what they need to do their job right. Eliminate the estimator's assumptions. Then make informed decisions with accurate information when needed to adjust the project costs.