Construction specifications are arranged by MasterFormat's 50 divisions and thousands of section numbers and titles - everyone knows that. There is a recent trend, at least with our architect clients, toward specifying complete systems and assigning responsibility to a single contractor to help ensure overall coordination and ultimate performance. An exterior wall, for example, may involve multiple MasterFormat spec sections - cladding, insulation, weather barrier, flashings, sealants, sheathing, stud framing, and possibly more. Is MasterFormat the right approach?

MasterFormat's Division 01 title "01 80 00 - Performance Requirements" provides a place to specify overall system performance of functional elements organized by UniFormat. Notations explain that this title is intended to include "other type requirements for systems and assemblies that include elements within multiple titles, in multiple divisions, or both" though the title seems restrictive.

Is MasterFormat the way to specify systems and assemblies?

The CONSTRUCT 2014 education session W02 - Evolving Specifications explored this question and discussed how UniFormat documents may be used as construction documents. Here is what CONSTRUCT attendees saw.

Briefly:

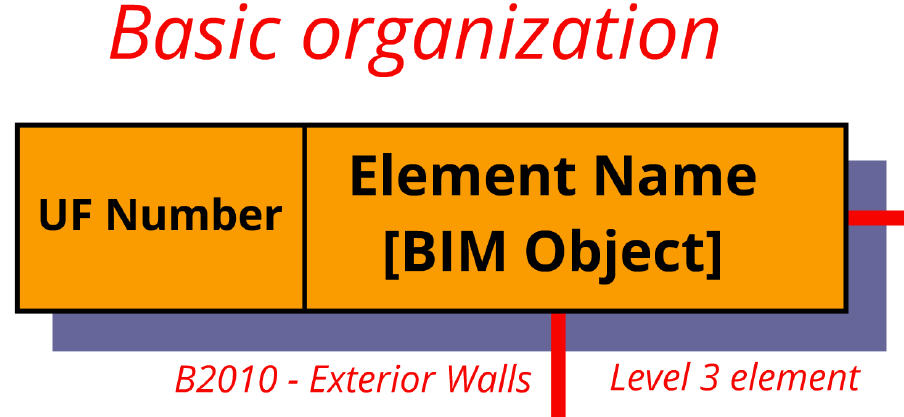

There are advantages to UniFormat, elemental, based documents. UniFormat describes systems and assemblies and BIM creates facilities graphically using objects representing systems and assemblies. The relationship between UniFormat elements and BIM objects is one-to-one. Every Revit BIM object includes an assembly code within the object properties. This code, as furnished by Revit, for each object is a UniFormat based number.

The assembly code allows the model objects to be queried and scheduled to determine what building systems are used for the particular project. The assembly code schedule will serve as the specifier's guide for the design team inquisition to determine what the project actually includes. The model may show only a generic exterior wall, an object with a volume, but without definition of materials.

That's okay. Consider using UniFormat to help the design process. The model need not identify the materials, especially if the exterior wall is not completely designed. Still the wall can be described before the designed solution is known. Certainly the performance can be determined for structural capacity, thermal resistance, air infiltration, and the like before the final design is known. The wall components can be determined later, selected to meet the stated performance. UniFormat based documents allow for progressive information. Document the performance, now; determine potential design solutions for consideration and evaluation against both cost and performance; and then document the final decisions when the information is available.

Using MasterFormat requires detailed material and product decisions to be able to select the correct number and title before starting the specifications. These decisions are often delayed until well into the construction documents phase - hopefully not beyond. MasterFormat based documents are reactive to design decisions rather than proactively helping guide the design team.

Conclusion:

So, let MasterFormat documents do what they do best: record finite decisions about material and product selections. Use UniFormat to assemble project data as the design progresses. Rely on UniFormat to describe the building functional elements including performance and components. Once decided, simply reference the necessary MasterFormat documents to specify the components required for each system and assembly.

UniFormat and MasterFormat can work together, complementing each other, to describe entire building systems and assemblies. UniFormat need not be inserted into MasterFormat. The documents can be maintained separately and both can be contract documents, simply different forms of specifications.

For those not attending CONSTRUCT, the presentation will be public following the show.