Efficiency isn't just about saving time, it's about leveraging knowledge and resources that guide the design team in decisions and capture information in the correct format, at the correct time in the process. It's about mitigating risk throughout the entire project. The Systems and Performance Description (SPD) is a way of documenting design in a highly efficient manner, offering tremendous value to the construction team. It combines an early project narrative with UNFORMAT® organization for ease of estimating. SPDs allow the designer to think about the assembly as a whole and capture information available at each phase – beginning at conception.

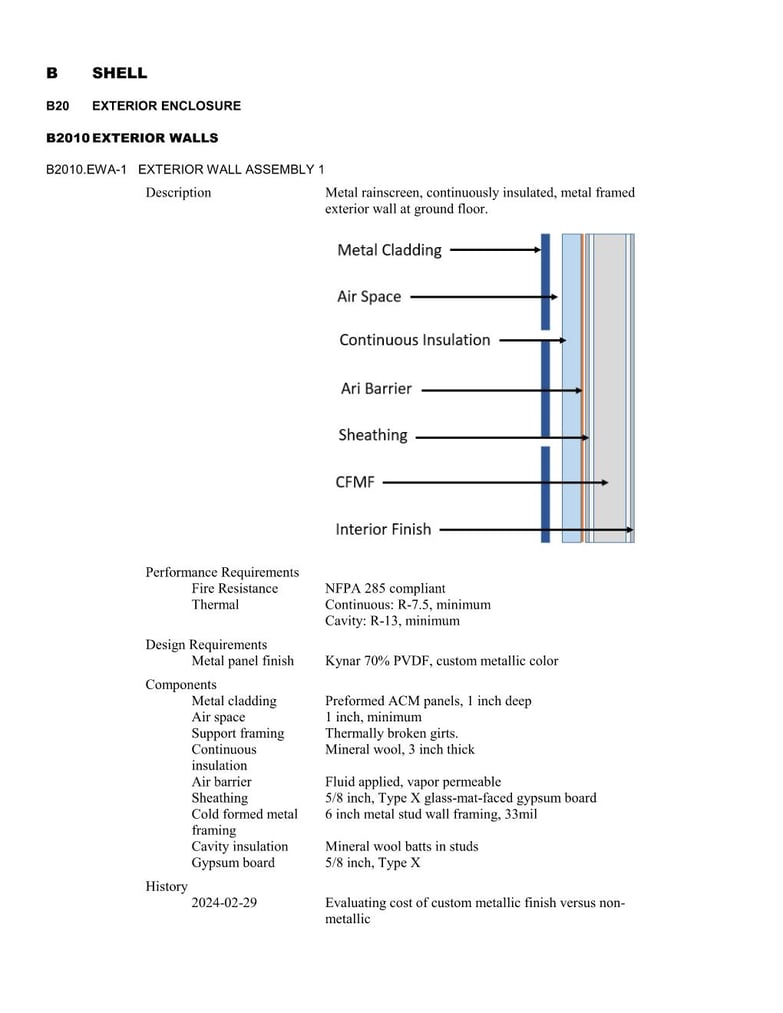

Let’s back up... What is an assembly? It's a collection of components that form an integrated system. Many Revit families are also assemblies. Why does this matter? Assemblies are powerful; they can communicate a wave of detailed information quickly and efficiently. One annotated assembly drawing can be referenced throughout the rest of the drawing to avoid repeating all the component detail notes in multiple places. Think of assemblies as a snapshot in the middle of the field - no terminations, no intersections. Assemblies get confusing and lose efficiency when they include too much detail, such as terminations and intersections with other assemblies.

As the design progresses, assemblies can be filled out more fully while there are still many unknowns. It's difficult to develop a MASTERFORMAT® specification section without knowing a basis-of-design product and how items are being installed, most of which are not known during Schematic Design (SD). Attempting to develop a full specification section so soon would involve guessing and then re-doing the work once decisions are finalized, or worse, listing every option available—it's not easy to estimate with excess information.

The SPD approach opens up opportunities for designers to explore system and assembly options before committing to a single design decision. It incorporates rigorous value analysis of the options to compare cost impacts, potential risks, and performance differences, helping to avoid reactive value engineering and design rework.

For drawings, assemblies can be taken from a library or can be developed quickly when something new is needed. In specifications, assemblies can be described in a single sentence that is easily understood, quickly comprehended, and easily estimated.

In specifications, assemblies can be described in a single sentence that is easily understood, quickly comprehended, and easily estimated.

Architectural and engineering drawings are filled with assemblies. Structural engineers may be the most proficient at using assemblies for footings, grade beams, pile caps, shear walls, floors, roofs, and more. Each location in plan is identified by a tag and each tag is scheduled or detailed only once. Architects generally rely on assemblies only for interior partitions.

Embrace the efficiency! What happens when architects extend their use of assemblies? The best example to discuss is exterior wall sections. Sections show footings, foundations, exterior walls, parapets, slabs on grade, elevated floors, and roofs. Each of these can be a designated assembly. The wall section can be shown with notes limited to tag numbers for each assembly. Intersections between floors and walls, for instance, can be keyed to a separate detail with notes about the intersection. The parapet termination can be keyed to a coping detail. The wall sections become a reference to assemblies and details.

The material notations exist on the drawings only once for each assembly and each detail. Minimizing the notation reduces potential conflicts and allows for a single point of control. Coordinate these with the written SPD and create better efficiency from concept through construction documentation.

Taking advantage of the power of assemblies can increase the efficiency of drawings. SPDs can bridge the gap in early design to hurdle right over value engineering. Now we're talking about efficiency that not only uses firm resources more wisely, but ripples out and saves time for all stakeholders involved in the project!